Standard

24 to 26AWG

To complete a Cat 6A patch cable, the two things listed below must be in your possession.

1. Workmanship – it takes a lot of practice to assemble a “REAL” Cat 6A patch cord on the field. The maintenance of twist-ratio, separation among pairs, stripped length, flush-cutting… etc. It is important to thoroughly consider each of these.

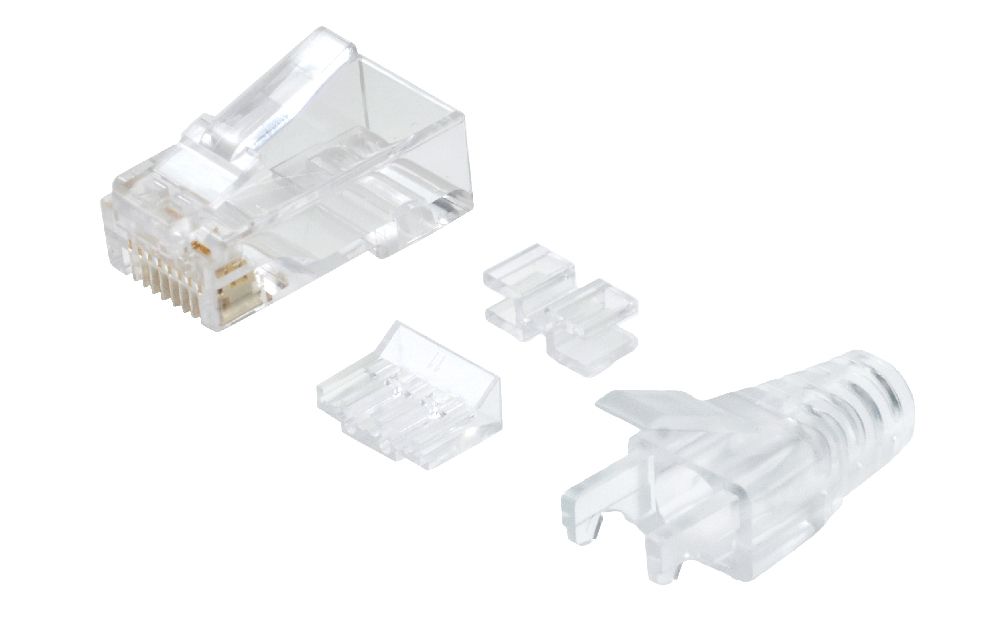

2. The right plug – 3-piece plug is recommended. The “guide” helps to separate each pair and keep its twist ratio. The “loading bar” is made to attach to the guide so each wire can be trimmed flush and steadily seated. Using the “right plugs” is the first important thing to do.

A 3-piece design that facilitates Cat 6A plug assembly is advised by HCI.

The standard 8-position groove/loading-bar inside the plug is 1.0mm+0.05/-0mm wide. The 3-prong blades enhance the certainty of piercing 24AWG to 26AWG stranded wires so excellent conductivity can be assured.

The fundamental component that enables you to connect to 10 Gigabit Ethernet.