Patch Cords

C5e / C6 / C6A

A patch cord is often called the “last mile” of a copper cabling channel. No installers are needed; any IT technician or authorized personnel can get the channel running once the permanent link behind the wall is properly set up. It might seem straightforward, but the quality of patch cords can make or break the network’s performance.

In the LAN industry, patch cords are typically seen as the weakest link in the entire cabling system. Why? Because the most significant signal interference happens when the plug mates with the jack. This connection can lead to unwanted crosstalk between pairs and disrupt impedance matching, which in turn causes signal reflections and noise. Ultimately, this can lead to network downtime and prevent the system from delivering promised speeds.

For a reliable channel, every component matters. A solid, component-rated setup is essential. For example, if you’re aiming for a fail-safe Cat 6 channel, make sure each part—cable, keystone jacks, patch panels, and the patch cord—meets the TIA-568.2-D and ISO-11801 Cat 6 component standards.

Now, let’s discuss Category X patch cords.

How does Cat 8 fit into the picture?

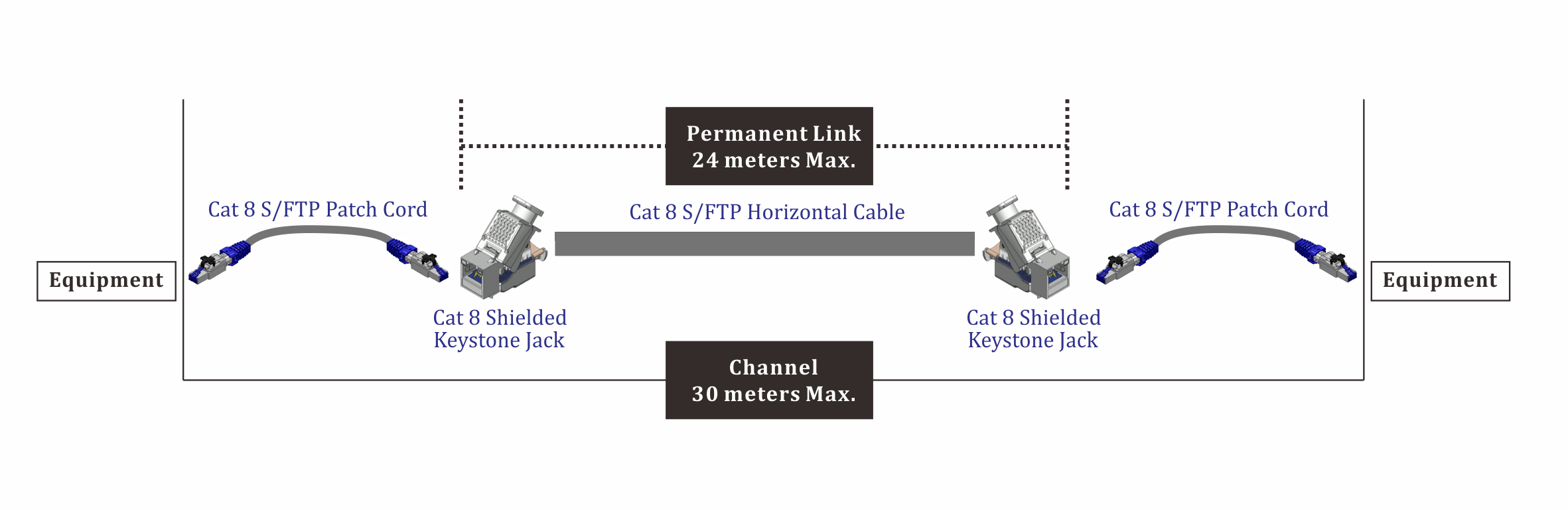

Cat 8 is designed for high-speed applications, supporting up to 25G and 40G, and is mainly deployed in data centers. According to the TIA standard, the maximum length for a Cat 8 patch cord is 6 meters (for both sides), while the ISO standard limits it to 4 meters. This also includes point-to-point permanent links. However, in most data centers, fiber optics are often preferred over copper cables. That’s one factor to consider.

Another issue with Cat 8 patch cords is that there are no commercially available patch cord test adapters for Cat 8 yet. Essentially, the Cat 8 patch cords currently on the market are labeled as “channel compliant,” meaning you can't test them using tools like the FLUKE Patch Cord Adapter that works for Cat 6A or Cat 6. In other words, achieving a reliable Cat 8 channel result depends on the overall system, not just the patch cord. It’s about the entire Cat 8 solution—cable, keystone jacks, patch panels, and the patch cord working together.

What about Cat 7?

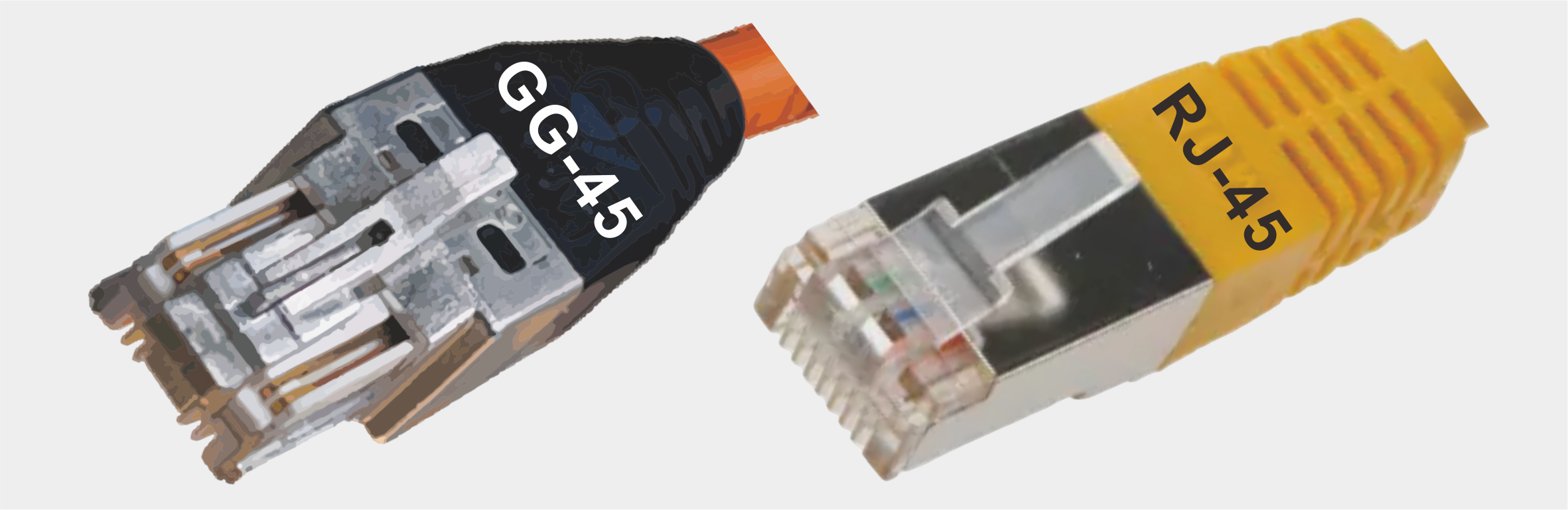

As for Cat 7, it’s been around for a while and is regulated by the IEC standard, but it hasn’t gained widespread adoption in North America. One key difference is its use of the GG-45 interface, rather than the more common RJ-45. When paired with a GG-45 Cat 7 keystone, a GG-45 Cat 7 patch cord can deliver a 10GBASE-T data rate up to 600 MHz. However, to reach that performance, the patch cord needs to be mated with a GG-45 keystone jack, such as those made by Nexans.

That said, Cat 7’s limited interoperability with existing infrastructure and its relatively slight edge over Cat 6A means it hasn't seen widespread adoption. Cat 6 and Cat 6A continue to dominate the market, with Cat 6A being the more practical and premium choice for copper cabling today.

Don't be fooled by patch cords labeled as Cat 7 that still feature the standard 8P8C connector like RJ-45. These are not true Cat 7; they're typically Cat 6A at most.

Cat 6A is the most future-ready option

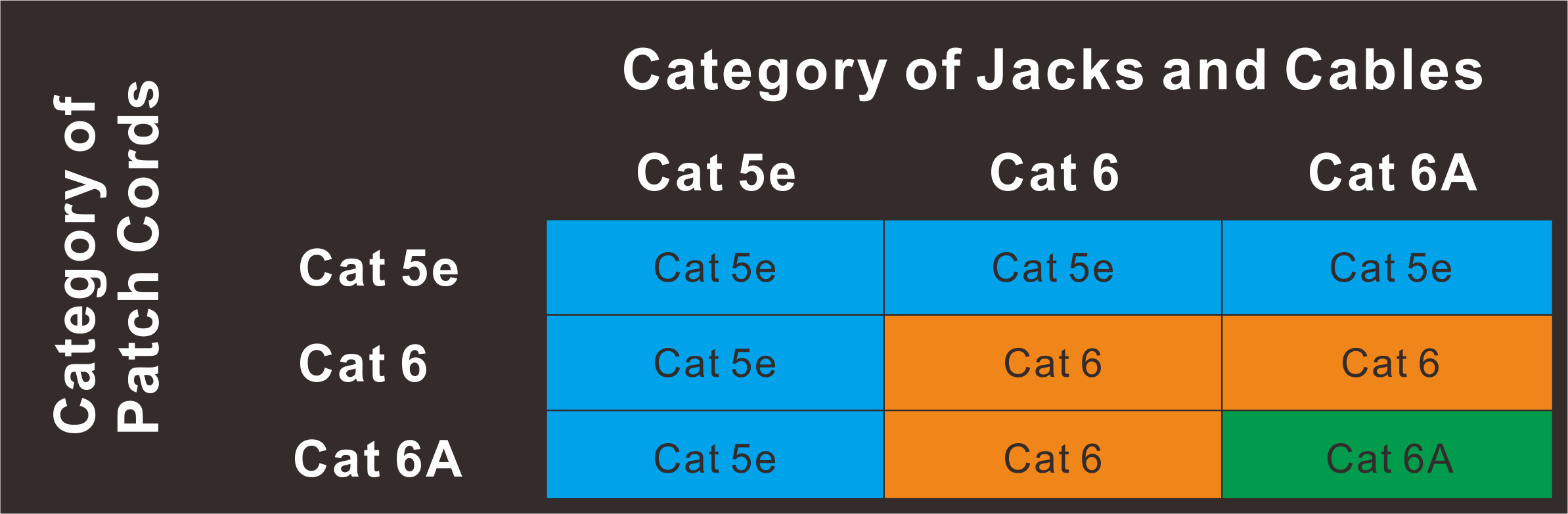

As explained earlier, Cat 6A is the clear choice for the current NBASE-T standard, no question about it. While Cat 6 is still a solid option and more than enough for mainstream use, Cat 5e is still around, but don’t push it to higher speeds. However, choosing the best patch cord isn’t always the answer – it's about selecting the right one for the job. For example, plugging a Cat 6A patch cord into a Cat 6 permanent link (cable with jacks) will only give you Cat 6 performance, not Cat 6A.

A guide to Patch Cord types

Patch cords may look similar at first glance, but their specifications can vary significantly. At HCI, we offer a wide range of options, all with one thing in common: Component-Rated performance. This means each patch cord meets the category standard on its own, without needing to be tested in combination with other parts. Here are a few key distinctions to help you choose the right patch cord for your specific needs.

1. Shielded or Unshielded?

The first decision in choosing a patch cord is whether to go shielded or unshielded. If the system is unshielded, selecting a shielded patch cord won’t add value since grounding won’t be effective. But if the system is shielded, a shielded patch cord is essential for grounding continuity. In Europe, strict EMC regulations make shielded patch cords mandatory for shielded systems, while outside Europe, unshielded patch cords are typically sufficient.

For high-speed data transmission, particularly with Cat 6A, alien crosstalk can be a concern. A shielded system with shielded patch cords helps guard against external noise, while an unshielded system can also meet Cat 6A standards if alien crosstalk is effectively managed.

2. Category 5e, 6 or 6A?

Choose the right category of patch cord to complete the system based on the project needs. For instance, match Cat 6A patch cords with a Cat 6A permanent links. While interfaces are interoperable and backward compatible, using a higher-category patch cord with a lower-category permanent link will still downgrade the entire channel to the lower category. In brief, Cat 5e and Cat 6 support Gigabit Ethernet, while Cat 6A is built for 10 Gigabit speeds.

According to standards, patch cords are typically limited to a total length of 10 meters, allowing for a 100-meter channel when combined with a 90-meter permanent link. However, longer patch cords—such as 20 meters—can be used if the de-rating factor is applied. When patch cords exceed 10 meters, the allowable permanent link length should be reduced from 90 meters to offset signal loss.

3. Component-Rated or Channel Compliant?

It’s not even an option here - HCI provides only premium "Component-Rated" Patch Cords, each 100% tested with a FLUKE DSX-8000 Patch Cord Adapter to comply with ISO-11801/TIA-568.2-D standards. This ensures IT personnel get reliable speed and performance, avoiding potential uncertainties that may arise with “channel-compliant” alternatives.

A test report for each individual patch cord or a QR code sticker for production traceability can be provided upon request. We stand behind every pack that leaves our assembly house with complete confidence in its quality.

4. 24AWG or Ultra-Slim?

The choice between 24AWG and ultra-slim cables ultimately comes down to proximity and space management. In environments where every rack unit counts, such as when aiming to fit 48 ports in 1U, ultra-slim cables (ranging from 28AWG to 32AWG) provide significant benefits. Their smaller size and flexible form allow for easier routing through ducts and trays, enabling a higher cable density with a smaller bending radius. This makes them ideal for tight spaces where cable management is key.

However, a trade-off comes with these thinner cables: they are more prone to signal attenuation due to their reduced gauge. The de-rating factor for ultra-slim cables can be as high as 50% compared to standard 24AWG cables. Therefore, careful planning is essential when combining the permanent link and patch cord length to avoid signal loss.

On the other hand, 24AWG patch cords are a solid choice for telecom and equipment rooms where cable density is less of a concern. With 24AWG, attenuation is less of an issue, making it a reliable option for maintaining signal integrity over longer distances.

5. Go Classic or Stand Out with Special Features?

With classic patch cords, the differences are not immediately obvious unless you test them and check the specified transmission speeds. However, when it comes to patch cords with special features, the differences are easy to spot just by looking at them. HCI offers a variety of these features, including colorful ID clips, retractable boots, sideways rotatable SR, die-cast plugs, and braided jackets.

Each special feature is designed for specific scenarios. While transmission speed remains the most important factor, it certainly doesn’t hurt to add extra value with features that enhance functionality or aesthetics.